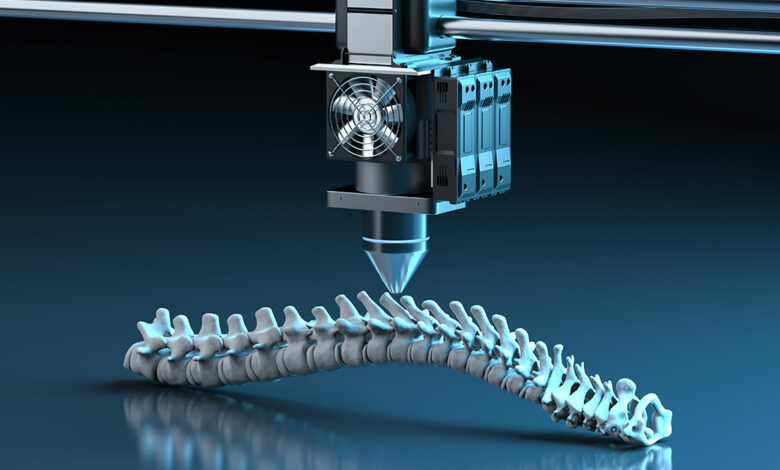

How 3d Printing Is Revolutionizing Prosthetics And Implants

How 3D Printing Is Revolutionizing Prosthetics and Implants, offering groundbreaking advancements that are reshaping the landscape of medical solutions. This technology is not only changing the way prosthetics and implants are designed and manufactured but also enhancing patient care by providing customized, affordable, and efficient solutions. With the rise of 3D printing in healthcare, we are witnessing a transformation that emphasizes personalization and innovation, promising better outcomes for patients across various medical fields.

Overview of 3D Printing in Medicine

The integration of 3D printing technology into the medical field has transformed the way healthcare providers approach patient treatment. Initially emerging in the late 20th century, this innovative technology has evolved significantly, facilitating the creation of customized medical devices, implants, and prosthetics tailored to individual patient needs. Such advancements have opened up new avenues for precision medicine, ultimately improving patient outcomes and experiences.

The significance of 3D printing in medicine cannot be overstated. This technology enables healthcare professionals to produce complex structures that are often unachievable with traditional manufacturing methods. For instance, 3D-printed implants can be designed to match the unique anatomy of a patient, ensuring better integration and functionality in the body. According to a market research report, the global 3D printing in healthcare market is expected to reach approximately $6.5 billion by 2026, highlighting an impressive growth rate driven by increasing demand for personalized medical solutions and advancements in printing technologies.

Evolution of 3D Printing Technology in Medical Applications

The journey of 3D printing in medicine began with the production of basic models for anatomical study. Over the years, the technology has progressed remarkably, leading to its application in creating surgical models, prosthetics, and even bioprinting tissues and organs. The following points illustrate key milestones in this evolution:

- In the 1980s, the first 3D printer was developed by Chuck Hull, laying the foundation for future innovations in various fields, including medicine.

- By the early 2000s, 3D printing was being used to create anatomical models that aided in surgical planning, allowing surgeons to practice complex procedures before operating on actual patients.

- In 2011, researchers successfully printed a human jawbone using a 3D printer, showcasing the potential for creating biocompatible implants that can integrate with human tissue.

- Recent advancements include bioprinting, where living cells are used to construct tissues and organs. This technology is currently in experimental stages but holds the promise of addressing organ shortages in the future.

The rapid growth of 3D printing in healthcare signifies its essential role in modern medicine. With ongoing research and development, this technology continues to shape the future of personalized healthcare solutions, making treatments more effective and accessible to patients worldwide.

Benefits of 3D Printing in Prosthetics

3D printing is transforming the landscape of prosthetic devices, bringing with it a host of benefits that significantly enhance patient care and experience. The technology stands out for its ability to create highly personalized devices that cater specifically to individual needs, thereby reshaping the traditional approach to prosthetic manufacturing. This innovation is not just about convenience; it is paving the way for improved patient outcomes and satisfaction.

One of the most prominent advantages of using 3D printing for prosthetics is the level of customization it offers. Traditional prosthetics often rely on generic molds and designs, which can lead to discomfort and a poor fit. In contrast, 3D printing allows for the creation of prosthetics that are tailored to the unique anatomy and lifestyle of each patient. This customization plays a crucial role in enhancing patient comfort and acceptance. For example, a prosthetic limb can be designed with specific features that accommodate the user’s daily activities, whether it’s for sports, work, or leisure.

Cost-Effectiveness of 3D Printed Prosthetics

The cost-effectiveness of 3D printed prosthetics compared to traditional methods is another significant benefit. The traditional manufacturing process can involve expensive materials and labor-intensive techniques, which often results in high costs for patients. In contrast, 3D printing streamlines production, minimizing waste and reducing material costs.

The following points illustrate the financial advantages of 3D printing in prosthetics:

Reduced Material Waste

– With traditional methods, excess materials are often discarded. 3D printing, however, uses only the necessary amount of material to create the prosthetic, leading to substantial savings.

Lower Labor Costs

– 3D printing automates many aspects of the manufacturing process, which can lead to lower labor costs and quicker production times. For instance, some prosthetics can be printed in a matter of hours.

Affordability for Patients

– As production costs decrease, the price of prosthetics can become more affordable for patients. This is crucial in providing access to those who may not have previously been able to afford a high-quality prosthetic device.

By shifting to 3D printing, the prosthetic industry can significantly lower costs while ensuring that patients receive devices that are not only functional but also personalized to their specific needs. This democratization of access to prosthetics can lead to improved quality of life for many individuals, reinforcing the importance of innovation in medical technology.

Innovations in Implant Technology: How 3D Printing Is Revolutionizing Prosthetics And Implants

The realm of implant technology is rapidly evolving, thanks in large part to the advancements in 3D printing. These innovations are not only enhancing the quality of implants but also improving patient outcomes significantly. With new materials and techniques emerging, 3D printing is poised to redefine the standards for medical implants.

New materials used in 3D printed implants are pivotal to enhancing their functionality and biocompatibility. Traditionally, implants have been made from metals and polymers, but advances in materials science have ushered in innovative alternatives that better mimic the properties of natural tissues.

Materials and Bioprinting in Implants, How 3D Printing Is Revolutionizing Prosthetics and Implants

The introduction of advanced materials such as bioactive glasses, ceramics, and even smart polymers has taken implant technology to new heights. These materials promote cell growth and integration with the body, leading to better healing and functionality.

Additionally, bioprinting represents a groundbreaking stride in implant technology. This process involves using living cells along with biomaterials to print tissues and organs layer by layer. The implications of bioprinting are vast, potentially allowing for the creation of custom organs that the body would not reject.

Several successful case studies highlight the benefits of 3D printing in implants. One notable example is the use of 3D printed titanium implants for patients with extensive bone loss. Researchers at the University of Maryland successfully used 3D printing to create a custom implant that restored function and improved the quality of life for a patient with significant facial deformities due to cancer.

In another case, a 3D printed mesh scaffold made from a biodegradable polymer was used to repair a critical bone defect in a young child. This implant facilitated natural bone growth and was eventually absorbed by the body, leaving behind a fully healed bone structure.

These examples underscore the transformative impact of 3D printing in the field of implant technology, setting a precedent for future innovations in medical treatments.

Collaboration Between Designers and Medical Professionals

The integration of 3D printing technology in the medical field has given rise to a new paradigm where collaboration between engineers and healthcare providers plays a critical role. This partnership is essential for developing customized prosthetics and implants that meet the specific needs of patients. By combining the technical expertise of designers with the clinical insights of medical professionals, a more effective and streamlined approach to healthcare innovation emerges.

Roles of Engineers and Healthcare Providers

In the 3D printing process, engineers and healthcare providers each have distinct but complementary roles. Engineers focus on the technical aspects of design, including material selection, structural integrity, and production feasibility. They utilize CAD (Computer-Aided Design) software to create precise models tailored to individual anatomical requirements. Healthcare providers, on the other hand, offer vital clinical knowledge and patient-specific data that inform the design process. Their input ensures that the final product not only fits well but also enhances functionality and comfort for the patient. This collaboration results in a product that is both innovative and practical, addressing the real-world needs of users.

Effective Communication Framework

To maximize the effectiveness of the collaboration between designers and medical professionals, establishing a clear communication framework during the design phase is crucial. This framework can be organized into several key components:

- Regular Meetings: Scheduled discussions between engineers and healthcare providers to review project progress and address concerns.

- Design Reviews: Joint evaluations of design iterations to ensure that clinical requirements are being met before moving to production.

- Feedback Loops: Mechanisms for ongoing feedback from healthcare providers to engineers, allowing for adjustments based on clinical insights.

- Documentation: Comprehensive records of design specifications and changes, which ensure all team members are aligned throughout the project.

By implementing these communication strategies, the likelihood of successful outcomes in the 3D printing process increases significantly.

Workflow from Design to Physical Creation

The transition from design to physical creation of prosthetics and implants involves a systematic workflow that ensures quality and efficiency. This workflow typically includes the following stages:

- Initial Consultation: Gathering detailed patient data and clinical requirements from healthcare providers.

- 3D Modeling: Engineers create digital models based on the collected data, ensuring alignment with medical specifications.

- Prototyping: Producing a preliminary version of the prosthetic or implant, which allows for initial testing and feedback.

- Refinement: Incorporating feedback from healthcare providers and making necessary adjustments to the design.

- Final Production: Utilizing 3D printing technology to fabricate the final product, ensuring all specifications are adhered to.

- Quality Assurance: Conducting thorough testing and validation of the final product to ensure it meets both engineering and medical standards.

This structured workflow fosters collaboration and enhances the overall quality of the final prosthetic or implant, ultimately leading to better patient outcomes. Each step is essential in bridging the gap between innovative design and practical application in the medical field.

Regulatory and Ethical Considerations

The integration of 3D printing into the medical field brings forth significant regulatory and ethical challenges. As this technology continues to evolve, ensuring that 3D printed medical devices meet safety and efficacy standards becomes paramount. Regulatory bodies like the FDA have stringent processes in place to evaluate new medical devices, and 3D printed products present unique hurdles in this regard.

Challenges in Obtaining Regulatory Approval

Acquiring regulatory approval for 3D printed medical devices is complex due to several factors. The customization and rapid production capabilities of 3D printing can complicate the traditional pathways for approval. Each device may be unique to the patient, raising concerns about quality control and reproducibility. Key challenges include:

- Variability in Manufacturing: Unlike conventional manufacturing processes, 3D printing can yield variations in materials and dimensions, leading to questions about consistency and reliability.

- Material Safety: Regulatory agencies require thorough evaluation of the materials used in 3D printing to ensure they are biocompatible and safe for human use.

- Validation of Printing Processes: Each printing process must be validated, which requires extensive documentation and testing to confirm that the devices perform as intended.

- Post-Market Surveillance: Ongoing monitoring of 3D printed devices post-approval is crucial to identify any long-term issues that may arise in diverse patient populations.

Ethical Implications of Customizing Prosthetics and Implants

Customizing prosthetics and implants for individual patients opens up various ethical considerations. The ability to create tailored solutions can significantly enhance patient outcomes, but it also raises questions about equity, access, and informed consent. Key considerations include:

- Equity in Access: Custom 3D printed devices may be significantly more expensive than traditional options, potentially limiting access for lower-income patients.

- Informed Consent: Patients must be fully informed about the risks and benefits of customized devices, requiring clear communication from healthcare providers.

- Intellectual Property Issues: The potential for proprietary designs can limit the availability of innovative solutions, raising concerns about monopolization in the market.

- Long-term Responsibility: Defining the responsibilities of manufacturers, designers, and healthcare providers in case of device failure is crucial for ethical practice.

Guidelines for Ensuring Patient Safety and Device Reliability

To ensure that 3D printed prosthetics and implants are safe and reliable, several guidelines should be adhered to throughout the design and manufacturing process. These guidelines address the need for rigorous quality assurance and patient safety mechanisms:

- Standardization of Processes: Establishing standardized protocols for the design, manufacturing, and testing of 3D printed devices is crucial to minimize variations and ensure quality.

- Comprehensive Testing: All devices should undergo extensive preclinical and clinical testing to validate performance, safety, and durability before reaching patients.

- Collaboration with Regulatory Bodies: Engaging with regulatory agencies during the development process can facilitate smoother approvals and ensure that all regulatory requirements are met.

- Continuous Monitoring and Reporting: Implementing systems for post-market surveillance can help identify potential issues early, ensuring ongoing patient safety.

“Ensuring the safety and efficacy of 3D printed medical devices is a shared responsibility among manufacturers, healthcare providers, and regulatory bodies.”

Future Trends in 3D Printed Prosthetics and Implants

The landscape of 3D printing in the medical field is on the brink of groundbreaking advancements that promise to transform prosthetics and implants. As technology evolves, we can expect enhanced designs, faster production times, and materials that are more biocompatible than ever before. This evolution will not only improve the functionality of devices but also expand accessibility for patients around the globe.

With the continuous growth of 3D printing technology, several trends are emerging that will significantly influence the future of prosthetics and implants. These advancements will incorporate innovations such as artificial intelligence (AI), bio-printing, and advanced materials to create personalized medical solutions. The shift from mass production to customized manufacturing is expected to revolutionize how we approach medical devices.

Advancements in Technology

The integration of advanced technologies will play a pivotal role in shaping 3D printing. Key advancements include:

– Artificial Intelligence: AI algorithms can analyze vast amounts of patient data to create customized prosthetic designs that cater to individual needs, enhancing comfort and functionality.

– Bio-printing: The ability to 3D print living tissues and organs opens new avenues for personalized implants and regenerative medicine, addressing the limitations of traditional prosthetic solutions.

– Material Innovations: Development of new materials such as smart polymers and bioactive ceramics that promote tissue integration will enhance the performance and longevity of implants.

New Applications Beyond Prosthetics and Implants

As 3D printing technology matures, its applications in the healthcare sector are expected to expand significantly. Possible new applications include:

– Customized Surgical Instruments: Tailored surgical tools designed for specific procedures can increase precision and reduce operation times.

– Organ Models for Surgical Planning: 3D printed organ models will allow surgeons to practice complex procedures beforehand, improving outcomes in actual surgeries.

– Dental Applications: From crowns to braces, the customization of dental solutions through 3D printing can enhance patient comfort and treatment effectiveness.

Emerging Companies and Innovations

Numerous companies are pioneering advancements in the 3D printing sector focused on healthcare. Some notable examples include:

– Organovo: Specializing in bio-printing, this company is at the forefront of creating functional human tissues for research and therapeutic applications.

– Carbon: Known for its pioneering Digital Light Synthesis technology, Carbon provides rapid prototyping solutions that are setting new standards in both implants and dental products.

– 3D Systems: This company is heavily invested in developing innovative 3D printing solutions for the medical field, including surgical guides and patient-specific implants.

These emerging trends and innovations signify a promising future for 3D printed prosthetics and implants, potentially leading to enhanced patient care and improved health outcomes.

Patient-Centric Approaches

3D printing is transforming the landscape of medical treatment, especially in prosthetics and implants, by placing patients at the center of their care. This technology not only enhances the production of medical devices but also significantly improves patient engagement, leading to personalized and effective treatment options. By involving patients in the design process and adapting solutions to their specific needs, the marriage of technology and empathy creates a more holistic approach to healthcare.

The ability to create custom prosthetics and implants tailored to individual anatomical features allows patients to feel more in control and invested in their treatment journey. Moreover, this shift towards patient-centric solutions has led to remarkable outcomes and success stories that highlight the transformative power of 3D-printed medical devices.

Patient Engagement and Success Stories

The incorporation of 3D printing into the medical field has driven patient engagement to new heights. Patients are encouraged to partake in discussions about their treatment, bringing their own preferences and experiences into the design process. This collaborative approach has led to numerous success stories, showcasing how personalized solutions can significantly impact quality of life.

One notable example is the case of a young girl who received a 3D-printed prosthetic arm that was designed based on her unique preferences, including a vibrant color and fun attachments that reflected her personality. This customization not only improved her functionality but also enhanced her confidence and social interactions.

Additionally, a man who lost his leg in an accident was able to use a 3D-printed prosthetic that perfectly matched the contours of his residual limb. The ability to achieve such a precise fit reduced discomfort and improved his mobility, allowing him to resume activities he loved, such as hiking and cycling.

Collecting and incorporating patient feedback is vital in refining the design process of 3D-printed solutions. Medical professionals and designers utilize various strategies to ensure that patient insights inform development, enhancing satisfaction and outcomes.

Methods of incorporating patient feedback include:

- Surveys and Questionnaires: Patients can express their opinions on design preferences, comfort, and functionality.

- Focus Groups: Engaging patients in discussions allows for a deeper understanding of their needs and experiences.

- Prototyping Sessions: Inviting patients to test prototypes fosters collaboration and enables real-time adjustments based on their feedback.

By prioritizing patient-centric approaches, the integration of 3D printing into prosthetics and implants not only enhances the technical aspects of medical devices but also nurtures a compassionate, responsive healthcare environment.

Wrap-Up

In conclusion, the intersection of technology and medicine through 3D printing is paving the way for a new era in prosthetics and implants. As advancements continue and challenges are addressed, the future holds immense potential for enhancing patient experiences and outcomes. By focusing on customization, collaboration, and ethical considerations, the medical community can harness the full power of this technology to improve lives and push the boundaries of what’s possible in healthcare.

FAQ

What are the main advantages of 3D printing in prosthetics?

The main advantages include customization for better fit and comfort, reduced production costs, and faster manufacturing times compared to traditional methods.

How does bioprinting differ from traditional 3D printing?

Bioprinting involves using living cells to create tissue-like structures, whereas traditional 3D printing typically uses non-living materials.

Are 3D printed implants safe for patients?

Yes, when produced under strict regulatory standards and quality controls, 3D printed implants are designed to be safe and effective for patient use.

Can 3D printing be used for all types of prosthetics?

While not all prosthetics are suitable for 3D printing, many types, especially those requiring customization, can greatly benefit from this technology.

What are the ethical concerns surrounding 3D printed medical devices?

Ethical concerns include issues of accessibility, the potential for misuse, and ensuring that patients receive safe and reliable products.